The Ultimate Guide to Diamond Plate Trailers

Diamond plate trailers are specialized hauling platforms featuring textured metal surfaces with a distinctive raised diamond pattern that provides durability, grip, and weather resistance.

| Diamond Plate Trailer Quick Facts | |

|---|---|

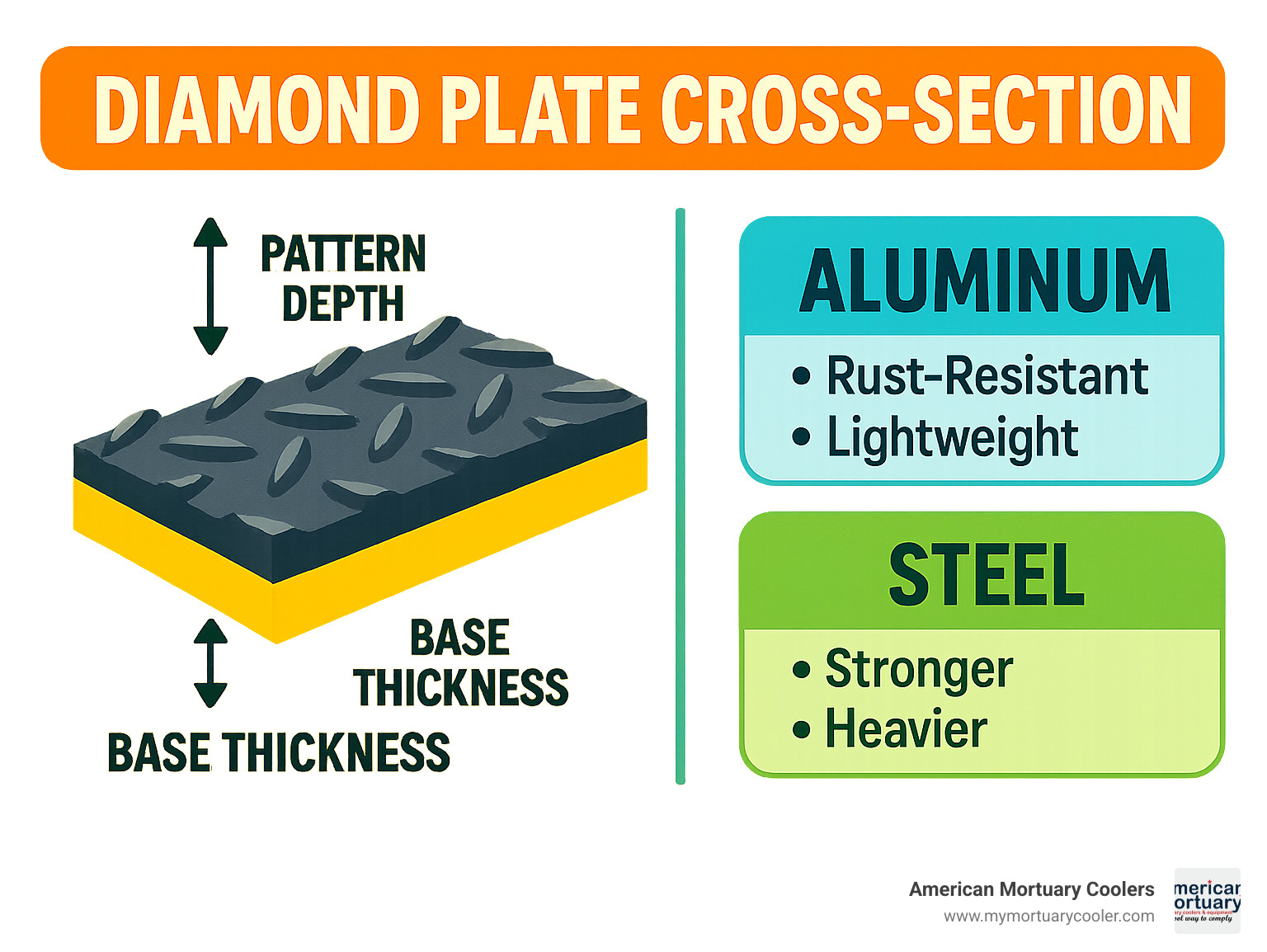

| Materials | Aluminum (rust-resistant, lightweight) or Steel (stronger, heavier) |

| Typical Thickness | Floors: 1/16" over wood, 1/8"-1/4" standalone Fenders: 0.056" thick |

| Key Benefits | Anti-slip surface, increased durability, weather resistance, scratch protection |

| Price Range | $2,899 - $36,999 depending on size and features |

| Common Uses | Equipment hauling, motorcycle transport, ATVs, commercial applications |

Diamond plate trailers stand out in the market for their distinctive appearance and practical benefits. The raised diamond pattern not only creates an iconic industrial look but serves multiple functional purposes. These trailers are ideal for hauling everything from construction equipment and motorcycles to lawn care machines and UTVs, offering superior protection against the elements and daily wear.

Real diamond plate is substantially thicker and stronger than imitation versions - authentic plate is typically 17GA (0.045" thick), which is 80% thicker than common 22GA (0.025" thick) stamped metal alternatives. This difference translates to significantly improved durability and longevity, making diamond plate trailers a wise investment for regular use in demanding conditions.

The material choice also matters significantly. Aluminum diamond plate won't rust, making it perfect for wet environments or coastal areas, while steel diamond plate offers greater strength for heavier loads but requires more maintenance to prevent corrosion. Both options provide the distinctive non-slip surface that makes loading and unloading safer in all weather conditions.

I'm Mortuary Cooler, a national supplier of specialized transport equipment with extensive experience configuring diamond plate trailers for funeral directors seeking reliable, customizable transport solutions. My expertise in diamond plate trailer applications comes from years of matching mortuary professionals with durable equipment built to withstand daily use while maintaining professional appearance.

Explore more about diamond plate trailer:

Diamond Plate Trailer Fundamentals

Shopping for a trailer that'll last? You'll want to understand what makes diamond plate trailers special. These eye-catching trailers aren't just about looks – that distinctive raised pattern on the metal surface offers real benefits while giving your trailer a professional, rugged appearance.

Diamond plate (sometimes called tread plate or checker plate) is a special type of metal sheeting with a regular pattern of raised diamonds or lines. This isn't just for show – it's a practical design that improves traction, resists scratches, and adds structural strength to your trailer.

| Feature | Aluminum Diamond Plate | Steel Diamond Plate |

|---|---|---|

| Weight | Lighter (1/3 the weight of steel) | Heavier |

| Corrosion | Will not rust | Susceptible to rust |

| Strength | Good strength-to-weight ratio | Stronger overall |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Minimal | Regular to prevent rust |

| Best for | Marine environments, weight-sensitive applications | Heavy-duty applications, maximum strength needs |

| Typical uses | Motorcycle trailers, ATV haulers | Equipment trailers, commercial applications |

"We've noticed funeral directors in coastal areas like Columbia, SC and Los Angeles consistently choose aluminum diamond plate because it won't corrode in salty air," shares our lead fabricator at American Mortuary Coolers. "Meanwhile, our Chicago and Midwest clients often prefer steel diamond plate trailers when they need maximum durability for heavy loads."

What Is a Diamond Plate Trailer?

A diamond plate trailer is a utility trailer that features diamond plate metal in key areas – typically the floor, sides, fenders, and sometimes toolboxes. That distinctive raised pattern isn't just attractive; it serves a real purpose while giving your trailer a professional, industrial look that stands out.

These versatile trailers are perfect for hauling construction equipment, landscaping machinery, motorcycles, ATVs, UTVs, golf carts, and all kinds of commercial equipment. In the funeral industry, they're valued for their dependable transport capabilities and professional appearance.

For those needing serious hauling power, the Diamond C PX312 triple-axle trailer represents the premium market segment. It can be upgraded with a 3/16" diamond plate floor for an additional $2,420.00 – worth every penny for heavy-duty applications where floor durability is essential.

If you're looking for something more budget-friendly, options like the 8 x 4 Golf Cart/Mower/Quad trailer with ramps (starting at $2,899.00) offer diamond plate features at a more accessible price point, perfect for small businesses or personal use.

Real vs Imitation Diamond Plate Trailer: How to Spot the Difference

Not all diamond plate is created equal – and the differences matter. Real diamond plate significantly outperforms imitation stamped versions in both strength and longevity. Here's how to tell what you're really getting:

Real Diamond Plate features solid diamonds when viewed from the back, is typically 17GA (0.045" thick), has substantial weight, displays a uniform pattern depth, and comes with a higher price tag reflecting its quality.

In contrast, Imitation Stamped Diamond Plate shows hollow diamonds on the back, is often just 22GA (0.025" thick), feels lighter, may have inconsistent pattern depth, and costs less – but at the expense of durability.

As one of our fabricators likes to joke, "They say diamonds are a girl's best friend... but who wants hollow diamonds?" It's a light-hearted way of making a serious point – authentic diamond plate offers about 80% more strength than imitation versions, which matters tremendously when you're hauling valuable equipment.

The easiest way to check? Just look at the backside of the plate. Real diamond plate shows solid diamonds on the reverse, while imitation stamped metal reveals hollow impressions.

Material & Thickness Benchmarks for Floors, Sides, Fenders

Choosing the right thickness for your diamond plate trailer components ensures you get the durability you need without paying for unnecessary weight or cost. Industry standards have developed based on real-world performance:

For trailer floors, you'll typically want 1/16" thick when installed over a wood subfloor, 1/8" to 1/4" thick when used as the only flooring layer, or 3/16" for heavy-duty applications like the Diamond C PX312 upgrade option.

Trailer sides generally feature 16" diamond plated solid sides (as in the Diamondplate model), reinforced with 10 C-channels for structural strength that won't buckle under pressure.

Fenders typically use .056" thick treadplate aluminum, which hits the sweet spot between durability and keeping weight manageable.

"Thickness requirements really depend on how you'll use the trailer," explains our engineering team. "For our mortuary transport trailers that serve funeral homes, we recommend at least 1/8" thick floors to handle the weight of loaded cots and equipment day after day without showing wear."

Benefits, Safety & Weather Performance

When it comes to hauling equipment, few trailer options offer the perfect blend of practicality and rugged good looks like a diamond plate trailer. Beyond their eye-catching industrial appearance, these trailers deliver real-world benefits that make them worth every penny for serious users.

That distinctive raised pattern isn't just for show – it creates a naturally slip-resistant surface that gives you confidence when loading equipment in less-than-ideal conditions. The textured surface provides crucial traction when you're wheeling heavy equipment up ramps or walking on the trailer bed during rainy days. This safety feature alone makes diamond plate worth considering for anyone who can't afford to postpone work just because of a little bad weather.

The durability factor is another game-changer. Diamond plate shrugs off the kind of abuse that would leave conventional trailer flooring looking shabby within months. Those raised diamonds distribute weight more effectively while protecting the surface from impacts and scrapes. We've seen diamond plate trailers at American Mortuary Coolers still looking professional after years of daily use – something our funeral director clients particularly appreciate.

"I've had my diamond plate equipment trailer for eight years now," shares one of our Tennessee customers. "It's hauled everything from backhoes to caskets, and besides needing a good wash now and then, it still looks almost new. Best investment I ever made for my business."

Weather resistance is another area where diamond plate truly shines. Whether you're dealing with scorching summer heat in our Southern service regions or brutal winter conditions up North, properly treated diamond plate holds up remarkably well. The material resists warping, cracking, and deterioration that plague many other trailer surface options.

Cleaning is refreshingly straightforward too – the smooth areas between diamonds don't trap debris the way some textured surfaces can. A simple pressure washing keeps everything looking professional with minimal effort.

Slip Resistance & Load Security

The non-slip properties of a diamond plate trailer make it a standout choice for professionals who can't afford workplace accidents. Those raised diamonds create hundreds of tiny edges that dramatically improve foot and tire traction compared to smooth metal surfaces.

For situations where even more grip is needed – like steep loading angles or extremely slick conditions – many of our clients apply strategic strips of high-quality grip tape like the Heskins Conformable Traction Tape. This creates designated high-traction zones exactly where you need them most. Some professionals also opt for sandblasting certain areas or using sandpaper to roughen specific spots for additional grip.

"We recommend creating what we call 'traction lanes' on your diamond plate ramps," explains our lead fabricator at American Mortuary Coolers. "By applying grip tape in two parallel strips exactly where tires will travel, you get maximum traction without covering the entire surface. It's economical and incredibly effective."

Load security is equally important, which is why quality diamond plate trailers typically feature numerous tie-down points. The popular 10,000 GVWR Deluxe Diamond Floor Equipment Trailer includes strategically positioned D-rings and stake pockets that make securing almost any load straightforward. This thoughtful design prevents shifting during transport – critical when you're hauling valuable equipment or sensitive cargo.

Longevity in Harsh Climates

Your location plays a big role in determining which diamond plate trailer material will serve you best. The choice between aluminum and steel isn't just about weight – it significantly impacts how your trailer will hold up over years of exposure to the elements.

Aluminum diamond plate is the undisputed champion for coastal regions and high-humidity environments. Unlike steel, it simply doesn't rust, making it ideal for our clients in places like Georgia, South Carolina, and along the Gulf Coast. Aluminum naturally forms a protective oxide layer that shields it from corrosion, meaning you'll spend your weekends using your trailer rather than maintaining it.

Steel diamond plate, while heavier, offers superior strength for extremely heavy loads. It's generally less expensive upfront, making it attractive for budget-conscious buyers in drier regions. However, steel requires vigilant maintenance to prevent rust, including regular inspections and touch-ups of protective coatings.

"We've seen the difference climate makes firsthand," notes our regional manager who oversees both our Tennessee headquarters and our coastal service areas. "Our inland clients with steel diamond plate trailers might go years with minimal maintenance, while the same trailer near saltwater would show rust spots within months without proper care."

Many premium diamond plate trailers now feature advanced powder-coated finishes that dramatically improve corrosion resistance. Diamond C's DM Powder Coating System, for example, provides significantly better protection than traditional wet paint, helping steel diamond plate withstand challenging environments much longer.

For the ultimate in weather resistance, look for aluminum diamond plate that meets rigorous ASTM standards (including B-632, B-137, MIL-A-8325F, B-136, and B-580 Type C). These certifications ensure your trailer will maintain its functionality and appearance even after years of exposure to harsh weather conditions and slip hazards.

At American Mortuary Coolers, we've found that our mortuary transport clients particularly value this durability – after all, their trailers need to maintain a professional appearance while functioning flawlessly in all conditions. Whether you're transporting the deceased or hauling heavy equipment, weather resistance isn't just about convenience – it's about reliability when it matters most.

Customization, Installation & Maintenance

Diamond plate trailers offer a world of personalization possibilities while maintaining their signature durability. Whether you're looking to match your company colors or add specialized features, these versatile trailers can be custom to your exact specifications.

Here at American Mortuary Coolers, we've noticed funeral homes increasingly requesting personalized trailer solutions that complement their existing fleet. Our Dallas and Pittsburgh customers particularly love color-matched diamond plate components that create a cohesive, professional look across all their vehicles.

Popular Models & Price Ranges

The diamond plate trailer market offers options for every budget and need, from basic utility models to sophisticated commercial equipment.

For those just starting out, entry-level options between $2,500-$5,000 include the nimble 7×4 Single Axle with Ramp at $3,199.00 or the budget-friendly Farm Bike/ATV Trailer at just $1,899.00. These provide the diamond plate benefits without breaking the bank.

Moving up to mid-range options ($5,000-$10,000), you'll find more substantial choices like the robust 10,000 GVWR Deluxe Diamond Floor Equipment Trailer priced at $6,290.00 – a favorite among our commercial clients for its perfect balance of capacity and value.

For those requiring premium performance, high-end models starting at $10,000+ include the impressive Diamond C PX312 Triple-Axle Trailer (starting at $35,085.00) or the fully-equipped Mobile Food Trailer with Diamond Plate at $36,999.00.

"Our Northeast customers typically gravitate toward those mid-range options with upgraded flooring," shares our sales director with a smile. "They want something substantial but not overbuilt for their needs. Meanwhile, our urban clients in New York and Chicago often select premium models with all the bells and whistles for their city-based funeral operations."

Common upgrades that affect pricing include diamond plate floor upgrades (about $2,420.00 for 3/16" plate), air ride suspension on longer models, adjustable cast couplers, and those handy HD V-Tongue storage compartments that provide secure storage for equipment.

Step-by-Step Installation Guide

Installing diamond plate on an existing trailer is a satisfying weekend project that pays dividends in durability and appearance. Here's how to tackle it with confidence:

Before you begin, gather your essentials: measuring tape, marker, drill with metal bits, self-tapping screws or rivets, safety gear, and ideally a helper for handling those unwieldy sheets.

Start by measuring twice (seriously, double-check everything!) before making any cuts. Clean the existing surface thoroughly – a solid foundation makes all the difference in the final result.

Next, do a test fit without fasteners to confirm proper alignment. This simple step saves headaches later. Once you're confident in the placement, mark and pre-drill your holes through the diamond plate and into the substrate.

The installation itself works best when you start securing the edges first with self-tapping screws or rivets, then work your way inward in a grid pattern, placing fasteners approximately every 12-18 inches. For floors especially, consider sealing the edges with an appropriate silicone or metal sealant to keep moisture at bay.

"When we install diamond plate floors in our mortuary transport trailers," our lead fabricator explains, "we're almost obsessive about creating watertight seals around the edges. It's crucial for maintaining proper sanitation in funeral applications – not something you want to compromise on."

Cleaning & Upkeep Tips

Keeping your diamond plate trailer looking sharp and performing well isn't complicated, but it does require some regular attention.

For routine cleaning, stick with mild soap and water – nothing harsh or acidic that might damage protective finishes. A microfiber cloth works wonders without scratching the surface. For aluminum diamond plate, applying automotive wax every 3-6 months keeps it gleaming and protected.

Steel diamond plate requires a bit more vigilance. Regular inspections for rust or corrosion pay off, as does promptly addressing any paint chips or scratches. A quick touch-up with protective coating prevents small issues from becoming big problems, especially if you're operating in coastal areas or winter road salt conditions.

Don't forget structural maintenance too. A quarterly check of fasteners, welds, seams, and tie-down points takes just minutes but can prevent major headaches down the road.

"Our funeral industry clients really appreciate how easy diamond plate is to thoroughly clean," notes our customer service team. "Between transports, they need surfaces they can sanitize completely, and diamond plate makes this process much more straightforward than textured alternatives."

For older diamond plate where traction has diminished, specialized products like SlipDoctors non-slip paint for metal surfaces can restore that essential grip without compromising the material's integrity. Similarly, conformable traction tape offers a quick solution for creating designated high-traction zones.

With proper care, your diamond plate trailer will maintain both its distinctive appearance and functional benefits for years to come, making it a wise investment for any serious hauling needs.

Frequently Asked Questions about Diamond Plate Trailers

Does Diamond Plate Rust or Corrode?

When it comes to rust and corrosion, not all diamond plate trailers are created equal. The material makes all the difference in how your trailer will hold up over time.

Aluminum diamond plate is essentially worry-free when it comes to rust. Instead of corroding, aluminum naturally forms a protective oxide layer on its surface – think of it as the metal's own built-in shield. This self-protecting quality makes aluminum diamond plate perfect for coastal areas where salt air is a constant threat, regions with heavy rainfall, or anywhere road salt is regularly used during winter months.

"I remember a funeral director in Virginia Beach who switched to aluminum diamond plate after fighting a constant battle with rust on his steel trailer," shares our product specialist. "Five years later, his trailer still looks almost new with minimal maintenance."

Steel diamond plate, while incredibly strong, does require more attention to prevent rust. Without proper care, steel will eventually surrender to moisture and oxygen, developing that familiar reddish-brown coating that weakens the metal over time. To keep steel diamond plate in prime condition, you'll need to maintain protective coatings, quickly address any scratches that expose bare metal, store it indoors when possible, and regularly clean off road grime and salt.

Our team at American Mortuary Coolers has equipped funeral homes from rainy Seattle to humid Miami, and we've consistently found that aluminum diamond plate delivers the best long-term value despite its higher upfront cost. The savings on maintenance time and extended service life quickly offset that initial investment.

How Thick Should My Diamond Plate Floor Be?

Choosing the right thickness for your diamond plate trailer floor is a bit like picking the right shoes for a job – go too thin and you'll regret it quickly, go unnecessarily thick and you're just adding weight and cost.

For trailers with a wood subfloor providing structural support, 1/16" (0.0625") diamond plate typically does the job nicely. The wood beneath handles the heavy lifting, while the metal layer provides protection and that distinctive non-slip surface. This combination gives you a smart balance of durability without excessive weight.

If your diamond plate will stand alone as the flooring (without wood underneath), you'll need to beef things up considerably:

- 1/8" (0.125") works for lighter loads like ATVs or garden equipment

- 3/16" (0.1875") handles medium-duty applications like construction tools

- 1/4" (0.25") stands up to truly heavy-duty use like industrial equipment

"We had a mortician in Chicago who initially tried to save money with thinner diamond plate," our fabrication manager recalls with a smile. "After a few months of daily use, he called us back for an upgrade. Sometimes you don't realize how important proper thickness is until you've tested the limits of something too thin."

For commercial applications, premium options like Diamond C's PX312 trailer offer a 3/16" diamond plate floor upgrade at an additional $2,420. That's not cheap, but for businesses using their trailers daily for heavy loads, it's an investment that pays dividends in longevity.

At American Mortuary Coolers, our standard for mortuary transport trailers is 1/8" aluminum diamond plate installed over marine-grade plywood. This combination has proven ideal for funeral industry needs – durable enough for daily use but not excessively heavy or expensive.

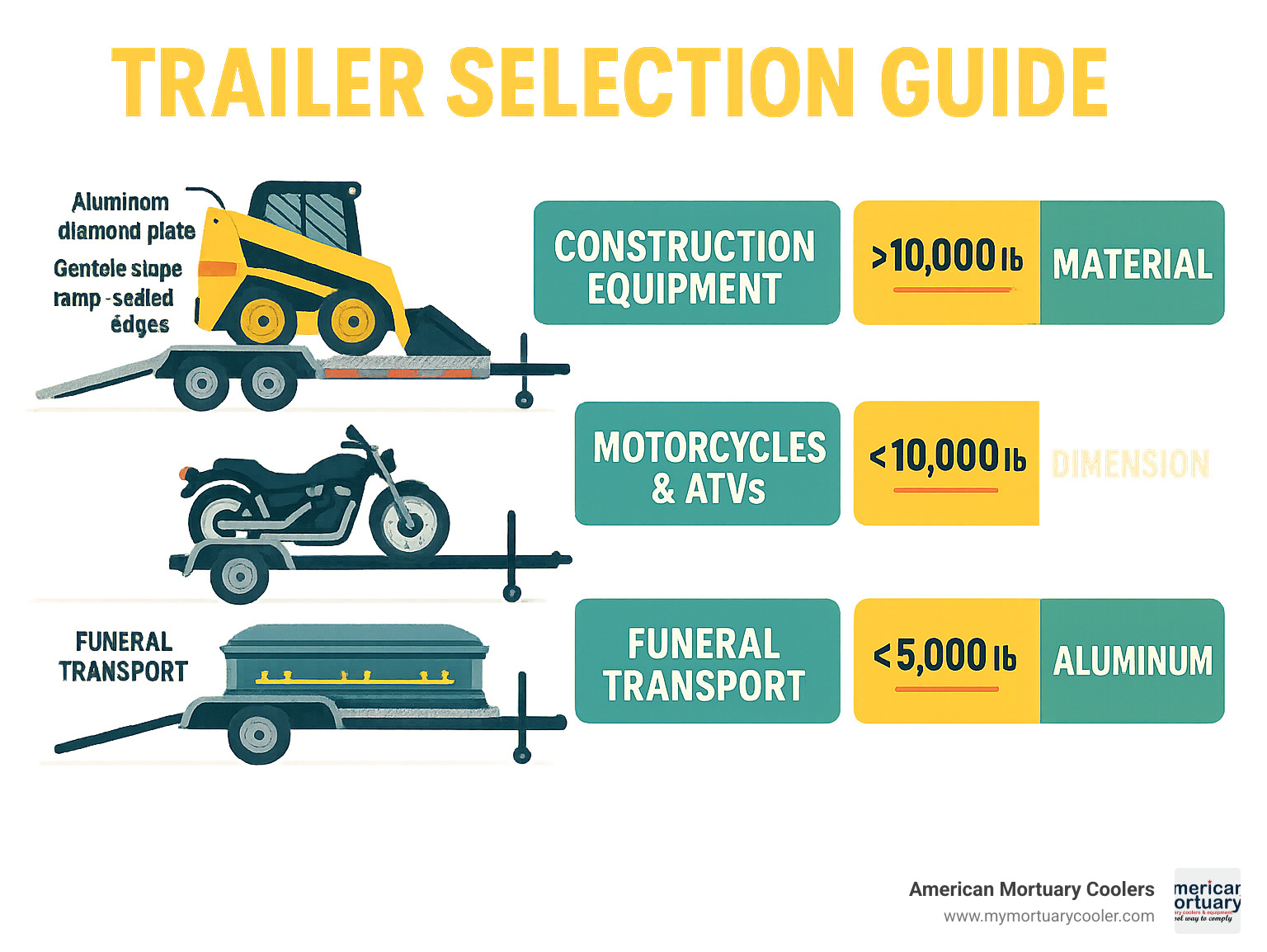

How Do I Choose the Right Diamond Plate Trailer?

Finding your perfect diamond plate trailer isn't about getting the most expensive model – it's about matching the trailer to your specific needs. Think of it like buying a suit – custom-fitted always works better than one-size-fits-all.

Start by honestly assessing what you'll be hauling. A landscaping business moving mowers and trimmers has very different needs than a funeral home transporting decedents. Consider both the weight and dimensions of your typical loads, plus how often you'll be using the trailer. Weekend warriors have different durability requirements than businesses using their trailer daily.

Your environment matters too. If you're in coastal Florida or rainy Oregon, aluminum's rust resistance might be worth the extra investment. For dry climates or maximum strength needs, steel could be the smarter choice. Aluminum saves on weight (typically a third lighter than comparable steel) but comes with a higher price tag upfront.

Budget considerations should include not just the purchase price – which can range from around $1,900 for basic models to $37,000+ for premium options – but also long-term maintenance costs and expected service life. Sometimes spending more initially saves thousands over the trailer's lifetime.

"One funeral director in Boston told me his diamond plate trailer was still going strong after 12 years of daily use," shares our customer service manager. "When you break down the cost over that kind of lifespan, even premium models start looking like bargains."

Pay close attention to specifications like GVWR (typically ranging from 7,000 to 40,000 pounds), deck length (14 to 40 feet), and ramp configuration. These details make the difference between a trailer that's perfect for your needs and one that's constantly frustrating to use.

For our funeral industry clients, we particularly emphasize ease of loading and unloading, plus features that improve sanitation. Gentle-slope ramps, sealed edges, and aluminum construction typically provide the best combination for mortuary transport needs.

At American Mortuary Coolers, we work with funeral directors from Seattle to Miami to create custom transport solutions that perfectly match their specific needs. Sometimes the right trailer isn't something you find – it's something you create with the right partner.

Conclusion

Diamond plate trailers truly represent the gold standard when it comes to hauling solutions. Their distinctive pattern isn't just eye-catching – it delivers real-world benefits that make a difference whether you're moving construction equipment across town or transporting specialized cargo for your business.

After exploring all the ins and outs of these remarkable trailers, a few key points stand out:

The material you choose makes a world of difference. Aluminum diamond plate gives you fantastic corrosion resistance and lighter weight – perfect if you're working in humid areas or need to maximize your payload. Steel, on the other hand, offers unbeatable strength when durability is your top priority, usually at a lower initial price point.

Don't be fooled by imitations! Real diamond plate (17GA/0.045") provides 80% more strength than those stamped look-alikes (22GA/0.025"). The easiest way to tell the difference? Check the back – authentic diamond plate shows solid diamonds on the reverse side, not hollow impressions.

When it comes to thickness, the right choice depends on your setup. If you're installing over a wood subfloor, 1/16" typically does the job beautifully. For standalone applications, you'll want 1/8" to 1/4", with heavier loads calling for the thicker end of that range.

One of the most practical benefits is the improved safety these trailers provide. That raised diamond pattern creates natural slip resistance that flat surfaces simply can't match. For even more grip, targeted treatments like specialized grip tape or surface texturing can make a significant difference during loading and unloading.

"We've heard from countless customers who appreciate how secure they feel when working on diamond plate surfaces, especially in wet conditions," notes our safety specialist at American Mortuary Coolers. "That peace of mind is invaluable when you're handling valuable equipment."

The customization possibilities are nearly endless. From specialized storage compartments to color-matched finishes that complement your company vehicles, modern diamond plate trailers can be custom to your exact specifications. This flexibility makes them ideal for businesses with unique requirements.

Perhaps most appealing is how simple these trailers are to maintain. Basic cleaning and occasional protective treatments are typically all that's needed to keep them looking great and functioning perfectly year after year.

At American Mortuary Coolers, we've incorporated diamond plate technology into our specialized transport solutions for funeral directors nationwide. From our home base in Johnson City, TN to our service locations across all regions, we've seen how these trailers deliver the perfect combination of durability, easy sanitation, and professional appearance that our industry demands.

"The investment in quality diamond plate pays dividends through extended service life and reduced maintenance," our product development team often reminds customers. "For professionals who rely on their equipment daily, the superior performance of genuine diamond plate is simply best."

If you're considering a diamond plate trailer for your specific needs, we'd be happy to discuss customized solutions that perfectly match your requirements. American Mortuary Coolers proudly serves funeral professionals across the contiguous 48 states with direct delivery of durable, custom equipment solutions that stand the test of time.